What is Supplier Relationship Management?

Strong relationships are the foundation of successful businesses. While much emphasis is often placed on building customer connections, supplier relationships are equally critical yet frequently overlooked. As businesses focus on supply chain resilience, the importance of Supplier Relationship Management (SRM) has grown.

Investing in supplier relationships benefits both your business and its vendor partners. Strong supplier relationships result in favorable terms and long-lasting partnerships. Discontented suppliers pose huge risks to your organization, potentially even leading to contract breaches.

To help you build productive partnerships, here are key tips for managing supplier relationships. Before that, let’s understand the concept of supplier relationship management.

Table of Contents:

- What is Supplier Relationship Management?

- Key Components of Supplier Relationship Management

- The Supplier Relationship Management Process

- Types of Supplier Relationships

- Best Practices for Supplier Relationship Management

- Objectives of Supplier Relationship Management

- Challenges (& Solutions) in Supplier Relationship Management

Jump to a section that interests you, or keep reading.

What is Supplier Relationship Management?

Supplier Relationship Management (SRM) is a structured approach that organizations use to evaluate, develop, and optimize their relationships with suppliers.

It goes beyond transactional procurement by focusing on building long-term, mutually beneficial partnerships that align with business goals. SRM is integral to modern supply chain strategies. It helps organizations to manage third-party vendors while improving collaboration, reducing risks, and fostering innovation.

Key Components of Supplier Relationship Management

Supplier Relationship Management (SRM) is built on several interconnected components that collectively ensure businesses can develop, maintain, and optimize relationships with their suppliers.

1. Supplier Segmentation

The first step in SRM is identifying and categorizing suppliers based on their importance to the business. Segmentation criteria include spend volume, criticality of goods or services, risk level, and innovation potential. This helps businesses prioritize their focus and tailor their engagement strategies for each supplier type.

2. Communication and Collaboration

Clear, open communication channels are central to a good SRM. Creating systems for regular interaction, whether in-person meetings, video calls, or digital collaboration tools, ensures that both parties can address concerns, share updates, and identify opportunities for mutual benefit. Collaboration extends to joint innovation efforts, co-developing solutions, or improving supply chain processes together.

3. Performance Monitoring and Evaluation

Measuring supplier performance through Key Performance Indicators (KPIs) is an essential SRM function. Metrics like lead time, defect rates, compliance with contract terms, and on-time delivery are used to assess how well suppliers are meeting expectations. Regular evaluations provide insights into strengths, weaknesses, and areas for improvement so that suppliers contribute positively to business goals.

4. Risk Management

Risk management is a critical component of SRM, particularly in today's volatile market. Organizations need to identify and mitigate risks related to delays, quality issues, compliance breaches, and external disruptions such as natural disasters or geopolitical events. Diversifying supply chains, monitoring supplier financial health, and developing contingency plans are some ways SRM helps address these risks proactively.

5. Contract and Compliance Management

Contracts form the foundation of supplier relationships. Good SRM ensures that agreements are clear, comprehensive, and aligned with business goals. These contracts detail pricing, service levels, responsibilities, and dispute-resolution mechanisms. Regular reviews of contracts help prevent misunderstandings, maintain alignment, and address business needs.

6. Technology Integration

Modern SRM relies heavily on technology to improve efficiency and transparency. Tools like supplier portals, automated onboarding systems, and performance dashboards enable real-time communication and data sharing. Advanced SRM platforms also incorporate artificial intelligence for predictive analytics, risk alerts, and sustainability tracking.

7. Innovation and Value Creation

SRM goes beyond operational efficiency to drive innovation. Through collaboration, suppliers can offer solutions that help businesses improve products, simplify processes, or reduce costs. Strong supplier relationships also emerge from co-development projects and joint research initiatives, delivering value to both parties.

8. Continuous Improvement

SRM is not static; it requires ongoing refinement. Organizations must regularly collect feedback, analyze performance data, and adapt their strategies to changing conditions. This iterative process ensures continuous improvement in supplier relationships, contributing to long-term success for both the business and its suppliers.

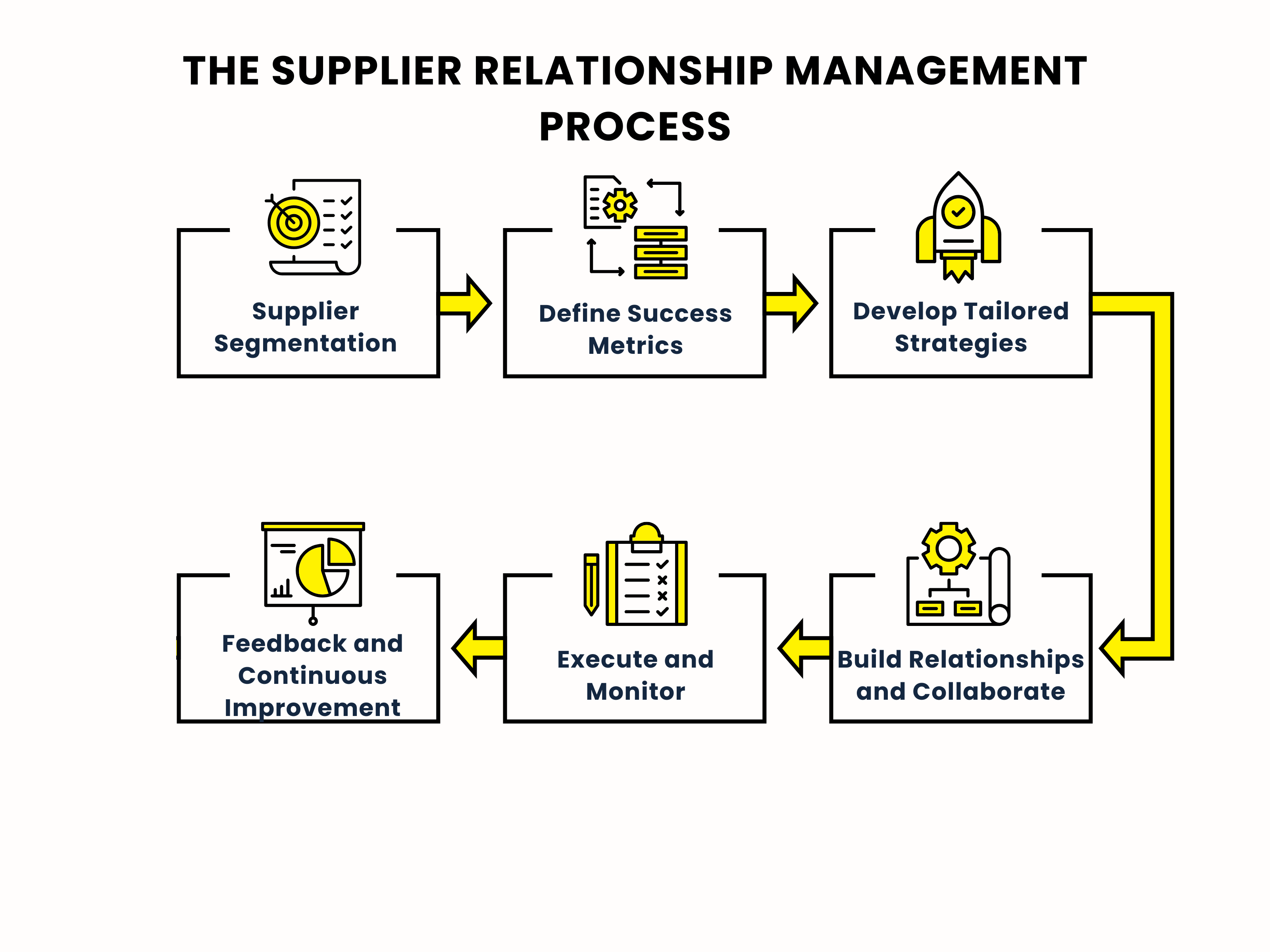

The Supplier Relationship Management Process

The Supplier Relationship Management (SRM) process is a structured approach designed to optimize relationships with suppliers, ensure operational efficiency, and foster long-term collaboration. Each step is essential to aligning supplier performance with organizational goals while addressing risks and opportunities.

1. Supplier Segmentation

Segmenting suppliers is the foundation of good SRM. This process involves categorizing suppliers based on their importance to the business and their specific roles in the supply chain. The criteria for segmentation include:

- Spend Volume: How much the organization spends with a supplier.

- Risk and Criticality: The supplier’s impact on operations and the difficulty of replacing them.

- Geographic Location: Proximity and exposure to regional risks, such as natural disasters or political instability.

- Innovation Potential: Suppliers’ ability to contribute to product or process improvements.

- Supply Chain Visibility: The extent to which supplier activities can be tracked and monitored.

Methods of Segmentation:

- Pyramid Approach: Categorizes suppliers into tiers based on strategic importance, with top-tier suppliers offering the most value and requiring the highest level of management.

- Value-Spend Quadrant: Maps suppliers based on the cost of their services versus their value to the business.

2. Define Success Metrics (KPIs)

Organizations need to establish clear and relevant Key Performance Indicators (KPIs) to measure supplier performance. These metrics provide insights into supplier contributions and highlight areas for improvement. The key KPIs include:

- On-Time Delivery Rate: The frequency with which suppliers meet delivery deadlines.

- Compliance with Contracts: Adherence to agreed terms and conditions.

- Defect Rate: The percentage of faulty or substandard goods delivered.

- Supplier Availability: The ability of suppliers to fulfill orders consistently.

- Lead Time and Responsiveness: The time taken to process and deliver orders and respond to inquiries.

3. Develop Tailored Strategies

Crafting customized strategies for different supplier segments ensures that resources are allocated.

- Strategic Suppliers: Develop long-term alliances, focus on collaborative innovation, and align goals for mutual benefit.

- Transactional Vendors: Prioritize cost efficiency, automate processes, and maintain minimal interaction.

Tailored approaches help address the specific needs and strengths of each supplier, fostering productive relationships.

4. Build Relationships and Collaborate

Strong relationships are at the heart of SRM. Building trust and collaboration leads to better communication, problem-solving, and shared innovation.

- Humanizing the Process: Regularly meeting suppliers, either in person or through video conferencing, strengthens the partnership.

- Joint Innovation Opportunities: Collaborate on co-developing products, improving processes, or solving challenges.

- Risk Management and Quality Improvement: Work together to address risks and enhance the quality of goods or services.

5. Execute and Monitor

Execution involves putting strategies into action and continuously tracking their outcomes. Technology plays a pivotal role in ensuring efficiency and transparency. Some SRM Software for execution:

- Contract Management: Ensures clarity in agreements and adherence to terms.

- Performance Tracking: Dashboards and analytics offer real-time insights into supplier performance.

- Automation: Simplify routine tasks such as order processing and performance evaluations.

6. Feedback and Continuous Improvement

The final step in the SRM process focuses on iterative improvement, ensuring relationships and processes evolve over time.

- Performance Evaluations: Conduct regular reviews to assess supplier effectiveness and address areas needing improvement.

- Supplier Self-Assessments and Surveys: Encourage suppliers to evaluate their own performance and provide feedback on the relationship.

- Data-Driven Refinements: Use insights from collected data to adjust strategies and improve outcomes continuously.

Types of Supplier Relationships

Supplier relationships vary significantly based on the level of collaboration and the role the supplier plays in achieving business objectives.

1. Transactional Relationships

Transactional relationships are characterized by short-term engagements focused on specific purchases. These suppliers typically provide routine goods or services with minimal interaction beyond placing orders and ensuring timely delivery. The emphasis is on cost, efficiency, and meeting immediate needs rather than building deeper connections.

2. Strategic Alliances

Strategic alliances involve deep, long-term partnerships where both parties work closely to achieve shared objectives. These suppliers are integral to the organization’s success, contributing to innovation, competitive advantage, or critical supply chain continuity. Strategic alliances involve collaborative projects, joint development, and shared gains.

3. Collaborative Partnerships

In collaborative relationships, suppliers and businesses cooperate beyond transactional needs to improve processes, enhance quality, or introduce innovations. These partnerships involve open communication, shared planning, and a focus on mutual benefits. Collaborative partnerships serve as the foundation for creating innovative solutions and addressing industry challenges.

4. Bottleneck Suppliers

These relationships occur with suppliers who provide essential items that are difficult to source or have limited alternatives in the market. While the engagement may not always be strategic, managing bottleneck suppliers is crucial to ensure supply chain stability and reduce dependency risks.

5. Vendor Relationships

Vendor relationships are straightforward and transactional, focused on fulfilling contractual obligations such as delivery timelines and compliance with service-level agreements. While they may not involve extensive collaboration, maintaining professionalism and fairness is important for efficiency.

6. Service-Based Suppliers

These suppliers provide specialized services rather than physical goods, often contributing to a company’s operations or strategy indirectly. Service-based relationships are commonly seen in areas such as IT support, marketing, or logistics, where expertise is critical.

7. Material and Product Suppliers

Material suppliers provide raw materials or components used in production, while product suppliers deliver finished goods. Both are essential for the supply chain but differ in their role and level of engagement.

8. Financial Providers

Although not traditional suppliers, financial providers such as banks, lenders, and investors support businesses by offering the financial backing needed for operations or growth. Managing these relationships ensures stability and access to necessary resources.

9. Business Partners

Business partners act as intermediaries or collaborators, helping organizations market, distribute, or sell products and services. These relationships extend beyond supply and involve mutual efforts to achieve market success.

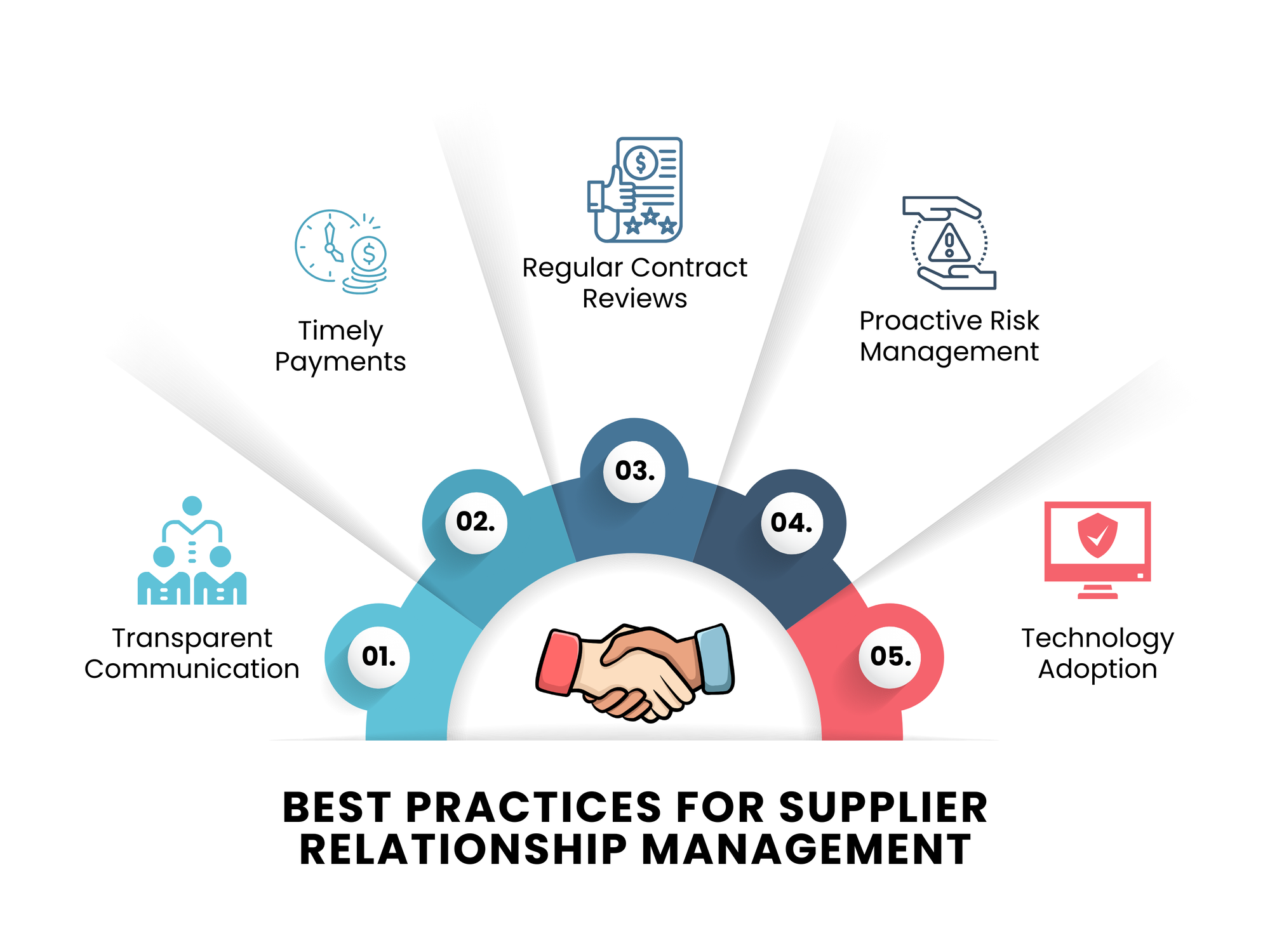

Best Practices for Supplier Relationship Management

Implementing best practices in Supplier Relationship Management is essential for fostering strong, reliable partnerships that enhance supply chain efficiency and resilience. These practices focus on trust, collaboration, and the strategic use of technology to drive mutual success.

1. Transparent Communication

Open and honest communication is the cornerstone of SRM. Regular updates, clear expectations, and accessible channels for feedback ensure both parties remain aligned. Transparency reduces misunderstandings, builds trust, and encourages proactive problem-solving. Whether through face-to-face meetings, video conferencing, or collaborative platforms, consistent interaction strengthens supplier relationships and builds a shared commitment to goals.

2. Timely Payments

Paying suppliers on time is a simple way to maintain goodwill and trust. Late payments can strain relationships and impact supplier performance, while prompt payments demonstrate reliability and respect. Suppliers who feel valued are more likely to prioritize your needs, offer favorable terms, and go the extra mile during critical situations.

3. Regular Contract Reviews

Contracts are the foundation of supplier relationships and define expectations and obligations. Regularly reviewing agreements ensures they remain relevant as business needs change. These reviews provide an opportunity to address any issues, renegotiate terms, and confirm mutual satisfaction. Proactive contract management prevents disputes, strengthens accountability, and reinforces the partnership.

4. Proactive Risk Management

Identifying and addressing risks early is vital to maintaining a stable supply chain. By diversifying suppliers, businesses can reduce dependency on a single source and mitigate vulnerabilities. Developing contingency plans for potential disruptions, such as natural disasters or geopolitical events, ensures readiness to adapt. Collaborating with suppliers to assess risks and establish mitigation strategies further improve resilience and supply chain continuity.

5. Technology Adoption

Using technology is key to modern SRM. Advanced tools, such as supplier portals, performance dashboards, and AI-driven analytics, improve efficiency, transparency, and decision-making. Automation simplifies routine tasks like order processing and performance tracking, freeing up resources for strategic activities. Real-time data sharing builds accountability and collaboration, while predictive analytics helps identify risks and opportunities.

Objectives of Supplier Relationship Management

The primary goal of Supplier Relationship Management is to maximize the value derived from supplier interactions while building strong, strategic partnerships. Achieving this requires a clear focus on cost efficiency, risk mitigation, innovation, sustainability, and strategic alignment.

1. Cut Costs and Improve Efficiencies

SRM aims to identify opportunities for cost reduction without compromising quality. By collaborating with suppliers, businesses can optimize processes, simplify procurement, and negotiate better terms. SRM also reduces operational inefficiencies, such as delays or redundant workflows, saving time and resources across the supply chain.

2. Reduce Risks and Ensure Continuity

Mitigating risks associated with supplier dependencies is a critical objective of SRM. Factors such as late deliveries, quality issues, or global disruptions can threaten business continuity. Through risk assessment and diversification, SRM ensures that contingency plans and alternative sources are in place, safeguarding the supply chain against unforeseen challenges.

3. Improve Supplier Responsiveness

Suppliers can be valuable partners in driving innovation. SRM supports collaboration to develop new products, improve existing solutions, and address evolving market demands. By maintaining open communication and building trust, businesses encourage suppliers to be proactive and responsive, particularly in adapting to urgent or unexpected needs.

4. Promote Sustainability and Diversity in Supply Chains

Modern SRM prioritizes sustainability and diversity to meet ethical and environmental standards. By engaging suppliers committed to sustainable practices, businesses reduce their environmental impact and enhance their social responsibility. Incorporating diverse suppliers, such as minority-owned businesses, also strengthens supply chain resilience and supports inclusive economic growth.

5. Align Supplier Strategies with Business Goals

Alignment between suppliers and organizational goals is essential for achieving long-term success. SRM ensures that suppliers understand and support the business’s objectives, whether through innovation, cost reduction, or expansion into new markets. This alignment creates a cohesive strategy that drives mutual growth and strengthens the partnership.

Challenges (& Solutions) in Supplier Relationship Management

Organizations must address these obstacles proactively to maintain strong partnerships.

1. Lack of Visibility

A common challenge in SRM is limited visibility into supplier operations and performance. Insufficient transparency can hinder decision-making, delay responses to issues, and lead to missed opportunities for improvement.

Solution: Advanced technologies like IoT, blockchain, and data-sharing platforms offer improved visibility. IoT sensors can provide real-time updates on inventory and shipments, while blockchain ensures secure and transparent transaction records. Data-sharing platforms help with smooth communication to build trust and accountability between businesses and suppliers.

2. Supplier Misalignment

Misalignment of goals, priorities, or expectations between businesses and suppliers can strain relationships and impact operational efficiency. Suppliers will not fully understand an organization’s objectives or their strategies will diverge over time, creating conflict.

Solution: Regular alignment meetings and periodic renegotiations help maintain clarity and mutual understanding. These interactions provide opportunities to realign objectives, address discrepancies, and ensure both parties remain on the same page. Establishing shared KPIs can also reinforce alignment and accountability.

3. Supplier Diversity and Inclusion

Striking a balance between maintaining deep relationships with key suppliers and promoting supplier diversity is a persistent challenge. While deep relationships ensure reliability and cost advantages, a lack of diversity can expose businesses to risks such as over-reliance or missed opportunities for innovation.

Solution: Businesses should broaden their supplier base by including diverse suppliers, such as minority-owned or women-owned businesses while maintaining strong partnerships with existing key suppliers. Supplier diversity programs promote resilience, agility, and compliance with social responsibility goals, creating a more inclusive supply chain without sacrificing efficiency.

4. Managing Continuity During Disruptions

Supply chain disruptions caused by events such as natural disasters, pandemics, or geopolitical instability pose significant risks to business continuity. Relying on a narrow supplier base or lacking contingency plans can exacerbate these vulnerabilities.

Solution: Building redundancy into the supply chain by diversifying suppliers and regions reduces dependency on any single source. Proactive communication with suppliers about potential risks and readiness strategies strengthens preparedness. Additionally, maintaining real-time data on supplier performance enables faster responses to unexpected disruptions.

Final Words

If you are new to Supplier Relationship Management, start with a few pilot projects on a smaller scale. SRM is an ongoing process, not a one-time initiative, and it extends beyond the procurement team. Regularly reviewing supplier performance with end-users and other stakeholders is important for reassessing key suppliers and their KPIs. Ultimately, SRM focuses on building strong and long-term relationships.