What is Foodservice Redistribution?

In the intricate network of the foodservice industry, the journey of products from manufacturers to end consumers involves multiple stages and intermediaries. Among these, foodservice redistribution plays a pivotal role in ensuring that products are efficiently moved, stored, and delivered to various foodservice operators, including restaurants, schools, and hospitals. This blog delves into the nuances of foodservice redistribution, examining its operational models, benefits, challenges, best practices, and emerging trends that are shaping the future of this essential industry component.

Table of Contents:

- What is Foodservice Redistribution?

- Benefits of Foodservice Redistribution

- Challenges in Foodservice Redistribution

- Best Practices for Effective Redistribution

- Future Trends in Foodservice Redistribution

Jump to a section that interests you, or keep reading.

What is Foodservice Redistribution?

Foodservice redistribution serves as a pivotal component within the food supply chain, facilitating the efficient movement of products from manufacturers to distributors, and ultimately to foodservice operators such as restaurants, schools, and hospitals. In this model, redistributors purchase large quantities of products from manufacturers, store them in their warehouses, and then sell these products in smaller, more manageable quantities to distributors. This approach allows distributors to access a diverse range of products without the need to meet the often substantial minimum order requirements set by manufacturers. By consolidating products from multiple manufacturers, redistributors streamline the procurement process for distributors, enabling them to offer a broader product selection to their customers.

Supply Chain Dynamics

In the traditional food supply chain, manufacturers produce goods and sell them directly to distributors, who then supply these products to foodservice operators. However, this linear model can present challenges, particularly for smaller distributors who may struggle with high minimum order quantities and limited storage capacity. The introduction of redistributors transforms this supply chain into a more flexible and efficient system. Redistributors act as intermediaries that bridge the gap between manufacturers and distributors. They purchase products in bulk from various manufacturers, store them in centralized warehouses, and then offer these products to distributors in quantities that align with their specific needs. This consolidation reduces the logistical burden on both manufacturers and distributors, leading to cost savings and improved service levels.

Roles of Manufacturers, Redistributors, and Distributors

-

Manufacturers: Responsible for producing food and related products, manufacturers often prefer to sell in large volumes to optimize production and logistics. However, not all distributors can accommodate such large orders. By partnering with redistributors, manufacturers can extend their market reach to smaller distributors without the need to manage numerous small-scale transactions.

-

Redistributors: These entities purchase large quantities of products from manufacturers and store them in their warehouses. They then sell these products in smaller quantities to distributors, effectively breaking down bulk orders into more manageable sizes. Redistributors handle the complexities of logistics and storage, allowing manufacturers to focus on production and distributors to concentrate on sales and customer service.

-

Distributors: Distributors purchase products from redistributors and supply them to foodservice operators. By sourcing from redistributors, distributors can access a wider range of products without needing to meet the large minimum order quantities set by manufacturers. This arrangement enables distributors to offer a diverse product portfolio to their clients, enhancing their competitiveness in the market.

Distinction Between Redistribution and Traditional Distribution

Traditional distribution involves a direct relationship between manufacturers and distributors, where manufacturers sell products in large quantities directly to distributors. This model can be challenging for smaller distributors who may not have the capacity to handle large orders or the storage facilities to accommodate them. In contrast, the redistribution model introduces an intermediary—the redistributor—that purchases bulk quantities from manufacturers and sells them in smaller, more manageable quantities to distributors. This model offers several advantages:

-

Reduced Minimum Order Requirements: Distributors can purchase smaller quantities of products, making it easier to manage inventory and reduce storage costs.

-

Access to a Broader Product Range: Redistributors consolidate products from multiple manufacturers, allowing distributors to offer a more diverse selection to their customers.

-

Streamlined Logistics: By handling bulk purchasing and storage, redistributors simplify the supply chain, reducing the logistical burden on both manufacturers and distributors.

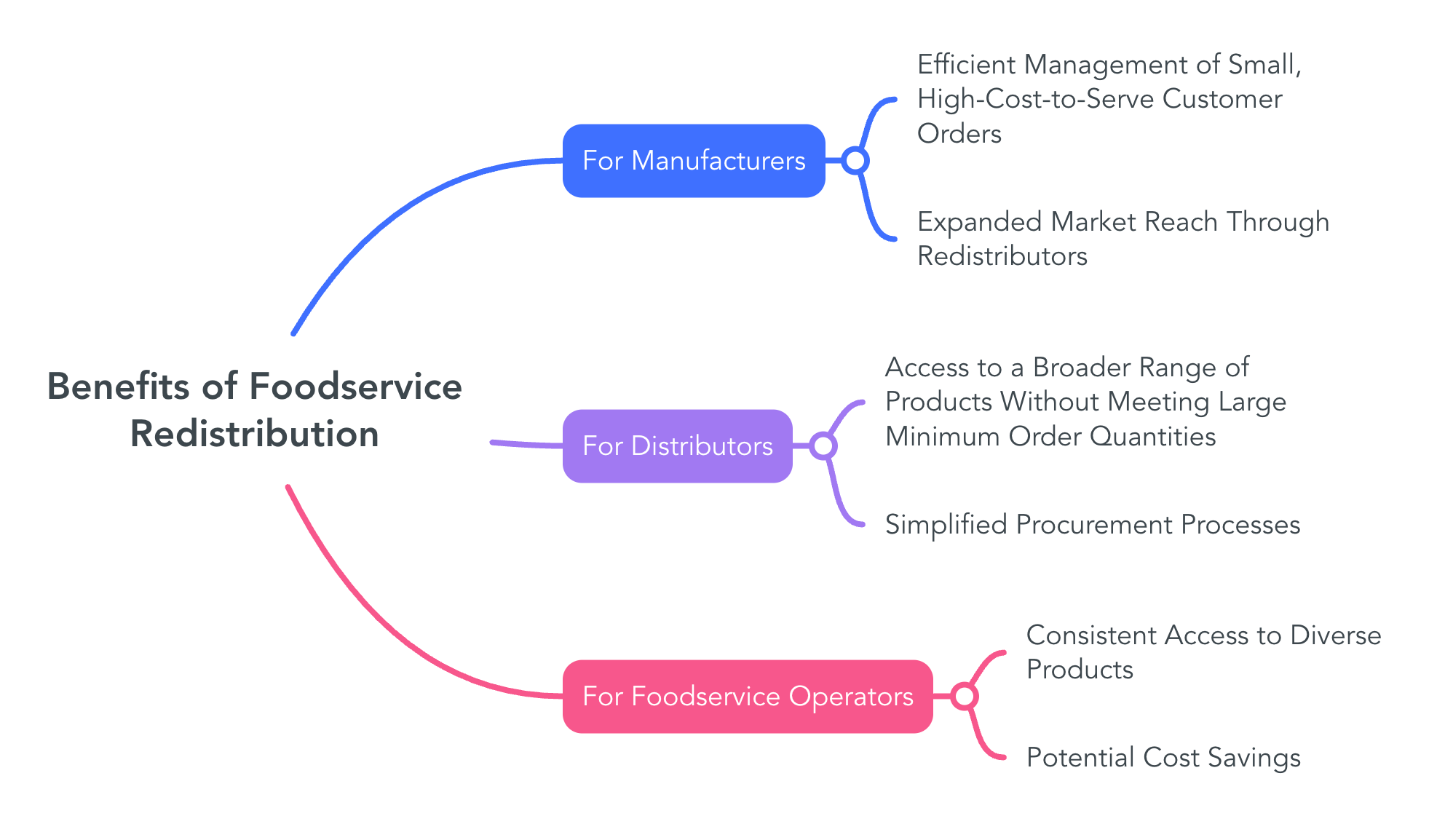

Benefits of Foodservice Redistribution

Foodservice redistribution offers significant advantages to various stakeholders within the supply chain, including manufacturers, distributors, and foodservice operators. By streamlining processes and enhancing accessibility, redistribution contributes to a more efficient and responsive foodservice industry.

For Manufacturers

-

Efficient Management of Small, High-Cost-to-Serve Customer Orders:

Manufacturers often encounter challenges when servicing small or geographically dispersed customers due to the disproportionate costs associated with fulfilling these orders. Foodservice redistributors address this issue by consolidating products from multiple manufacturers and distributing them in quantities that meet the specific needs of smaller distributors and operators. This consolidation allows manufacturers to focus on large-scale production and bulk shipments, reducing logistical complexities and associated costs. According to Honor Foods, this approach decreases the barrier of entry for smaller distributors, affording them the same opportunities as their larger competitors.

-

Expanded Market Reach Through Redistributors:

Collaborating with redistributors enables manufacturers to penetrate markets that might otherwise be inaccessible due to logistical constraints or limited sales infrastructure. Redistributors possess established networks and local market knowledge, facilitating the introduction of manufacturers' products to a broader customer base. As noted by Burris Logistics, redistributors excel at introducing food suppliers to previously unknown customers, thereby increasing market share and business growth.

For Distributors

-

Access to a Broader Range of Products Without Meeting Large Minimum Order Quantities:

Distributors often face challenges in sourcing a diverse product range due to manufacturers' minimum order requirements, which can be prohibitively large. Redistributors mitigate this issue by purchasing in bulk from manufacturers and offering these products to distributors in smaller, more manageable quantities. This arrangement allows distributors to diversify their offerings without the financial strain of large inventory investments. Food Business Review highlights that food redistribution enables distributors to order products in quantities as small as a single case, eliminating the need to meet manufacturer volume requirements.

-

Simplified Procurement Processes:

By sourcing a wide array of products from multiple manufacturers through a single redistributor, distributors can streamline their procurement operations. This consolidation reduces administrative burdens, simplifies logistics, and enhances operational efficiency. Honor Foods emphasizes that working with a foodservice redistributor can level the playing field for smaller distributors, providing excellent value in terms of cash flow and inventory management.

For Foodservice Operators

-

Consistent Access to Diverse Products:

Foodservice operators benefit from the redistributor's ability to supply a wide variety of products consistently. This consistent access ensures that operators can meet customer demands and maintain menu offerings without disruptions. Quirch Foods underscores the importance of reliable distribution networks in keeping restaurants stocked with the necessary ingredients to serve fresh, high-quality meals.

-

Potential Cost Savings:

By reducing the need for operators to engage with multiple suppliers and manage complex logistics, redistributors contribute to cost efficiencies. Operators can place consolidated orders, reducing administrative expenses and benefiting from the redistributor's economies of scale. Additionally, redistributors often offer flexible ordering options, allowing operators to purchase quantities that align with their specific needs, thereby minimizing waste and optimizing inventory management. As highlighted by Quirch Foods, partnering with a trusted food distributor can save time and money through efficient inventory management and waste reduction strategies.

Challenges in Foodservice Redistribution

Foodservice redistribution plays a pivotal role in bridging the gap between manufacturers and foodservice operators. However, this process is fraught with challenges that can impact efficiency, product quality, and stakeholder coordination.

Managing Complex Supply Chains

The foodservice supply chain encompasses a vast network of manufacturers, redistributors, distributors, and foodservice operators. Coordinating the movement of products through this intricate web presents several challenges:

-

Demand Forecasting: Accurately predicting demand is critical to prevent overstocking or stockouts. The perishable nature of many food products adds urgency to this challenge, as miscalculations can lead to waste or unmet customer needs.

-

Logistical Coordination: Ensuring timely deliveries requires meticulous planning, especially when dealing with multiple suppliers and customers across various regions. Factors such as transportation delays, weather conditions, and geopolitical issues can further complicate logistics.

-

Regulatory Compliance: Adhering to food safety standards and regulations across different jurisdictions necessitates constant vigilance and adaptability. Non-compliance can result in legal repercussions and damage to reputation.

According to Food Logistics, the food distribution sector has faced numerous disruptions, including supply chain interruptions and logistical challenges, over recent years.

Ensuring Product Quality and Safety During Transit

Maintaining the integrity of food products from the point of origin to the end consumer is paramount. Challenges in this area include:

-

Temperature Control: Many food items require strict temperature management to prevent spoilage. Any deviation during transit can compromise product safety and quality.

-

Handling Procedures: Improper handling can lead to contamination or physical damage. Ensuring that all personnel involved are trained in proper food handling practices is essential.

-

Traceability: In the event of a product recall, being able to trace a product's journey through the supply chain is crucial for swift action. Implementing robust tracking systems can aid in this process.

Food Logistics emphasizes that enhancing food safety within the supply chain involves a combination of people, processes, and technologies.

Coordinating Between Multiple Stakeholders

Effective communication and collaboration among all parties in the foodservice redistribution chain are vital. Challenges include:

-

Information Sharing: Discrepancies in data or lack of transparency can lead to misunderstandings and errors. Establishing standardized communication protocols can mitigate this issue.

-

Conflicting Objectives: Different stakeholders may have varying priorities, such as cost reduction versus quality assurance. Aligning these objectives requires negotiation and compromise.

-

Technology Integration: Integrating various technological systems used by different stakeholders can be complex but is necessary for seamless operations.

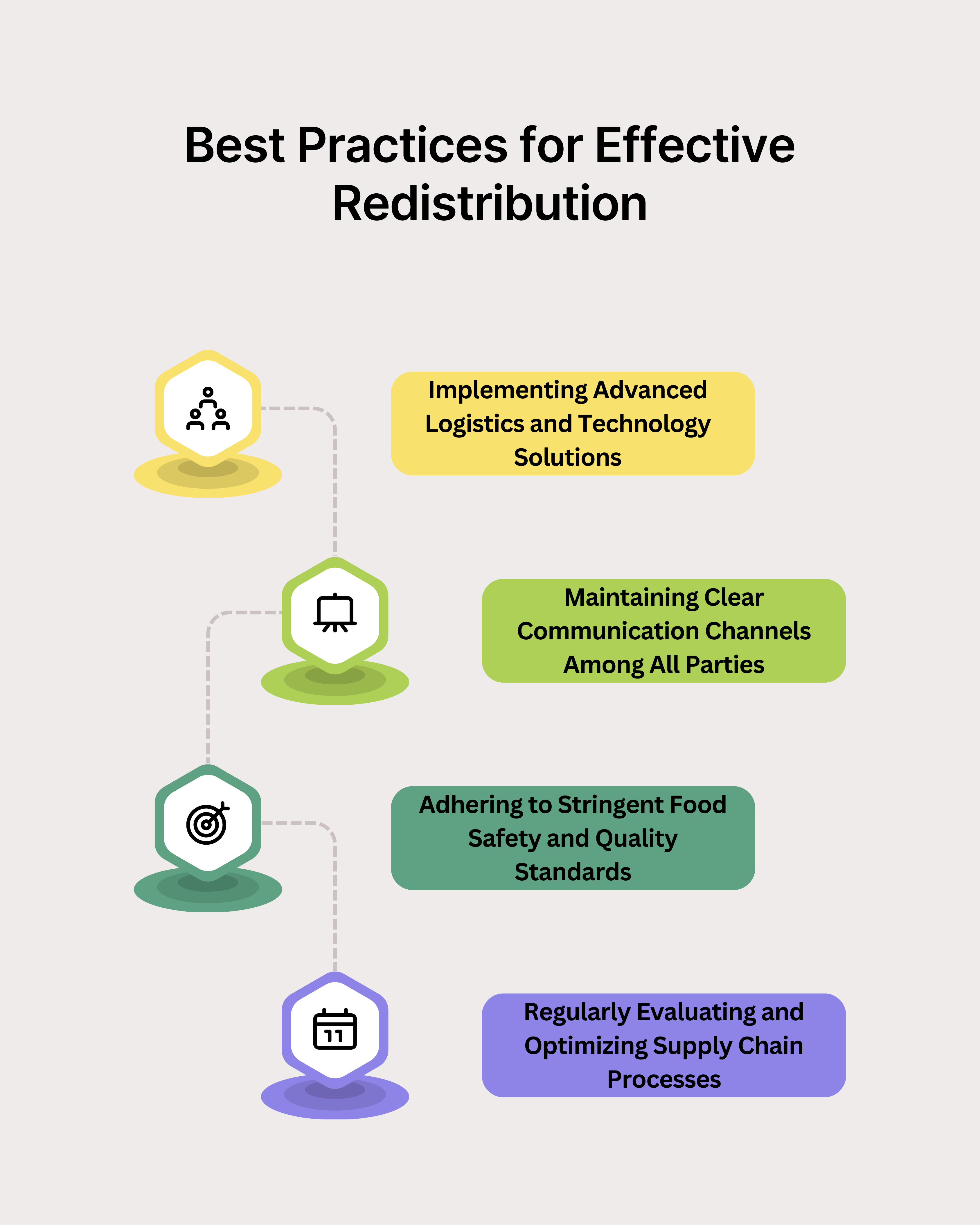

Best Practices for Effective Redistribution

Effective foodservice redistribution necessitates a strategic approach that integrates advanced logistics, clear communication, stringent adherence to food safety standards, and continuous supply chain evaluation. Implementing these best practices ensures operational efficiency, product integrity, and customer satisfaction.

Implementing Advanced Logistics and Technology Solutions

Leveraging modern technology is crucial for optimizing logistics in foodservice redistribution. Key strategies include:

-

Route Optimization: Utilizing advanced route planning tools enables efficient management of multi-stop deliveries, reducing fuel consumption and delivery times. These systems balance destinations across routes, ensuring timely deliveries that meet customer requirements.

-

Inventory Management Systems: Implementing robust inventory management solutions provides real-time visibility into stock levels, facilitating accurate demand forecasting and minimizing overstocking or stockouts. This leads to reduced waste and improved order fulfillment rates.

-

Data Analytics: Employing predictive analytics and machine learning algorithms assists in identifying trends and potential disruptions, allowing for proactive decision-making and enhanced supply chain resilience.

Maintaining Clear Communication Channels Among All Parties

Transparent and consistent communication is vital for synchronizing activities among manufacturers, redistributors, distributors, and foodservice operators. Best practices include:

-

Regular Meetings: Conducting periodic meetings fosters alignment of goals and expectations, facilitating collaborative problem-solving and strategy development.

-

Information Sharing Platforms: Utilizing centralized digital platforms enables real-time information exchange regarding inventory levels, delivery schedules, and potential issues, enhancing responsiveness and coordination.

-

Feedback Mechanisms: Establishing channels for stakeholders to provide feedback promotes continuous improvement and swift resolution of concerns, strengthening partnerships and operational efficiency.

Adhering to Stringent Food Safety and Quality Standards

Ensuring product safety and quality throughout the redistribution process is imperative. Key measures include:

-

Compliance with Regulations: Strict adherence to food safety standards, such as the Food Safety Modernization Act (FSMA) and Good Manufacturing Practices (GMP), is essential for legal compliance and consumer protection.

-

Employee Training: Regular training programs on proper food handling, sanitation, and safety protocols help prevent contamination and maintain product integrity.

-

Traceability Systems: Implementing traceability solutions allows for tracking products throughout the supply chain, facilitating quick responses to recalls and ensuring accountability.

Regularly Evaluating and Optimizing Supply Chain Processes

Continuous assessment and refinement of supply chain operations are critical for sustained efficiency and competitiveness. Strategies include:

-

Performance Metrics: Defining and monitoring key performance indicators (KPIs) related to delivery times, order accuracy, and inventory turnover aids in identifying areas for improvement.

-

Lean Principles: Applying lean methodologies focuses on waste reduction and process optimization, enhancing overall productivity and cost-effectiveness.

-

Technology Upgrades: Regularly updating technological tools and systems ensures alignment with industry advancements and evolving business needs, maintaining a competitive edge.

Future Trends in Foodservice Redistribution

The landscape of foodservice redistribution is undergoing significant transformation, driven by technological innovations, a heightened focus on sustainability, and evolving consumer preferences. These factors are reshaping how products are distributed, emphasizing efficiency, environmental responsibility, and responsiveness to market demands.

Impact of Technological Advancements

Technological progress is revolutionizing foodservice redistribution by enhancing operational efficiency and accuracy. Key developments include:

-

Automation and Robotics: The integration of robotic systems in foodservice operations is streamlining tasks such as food preparation and packaging, leading to increased efficiency and consistency. For instance, robotic arms are now capable of preparing complex dishes with precision, reducing labor costs and improving service speed.

-

Advanced Forecasting and Data Analytics: Utilizing data analytics enables more accurate demand forecasting, inventory management, and route optimization. Predictive analytics help in anticipating market trends and adjusting supply chains proactively, thereby reducing waste and improving service levels.

-

Artificial Intelligence (AI): AI applications are becoming more prevalent in food logistics, assisting in decision-making processes, enhancing customer service through chatbots, and optimizing delivery routes. The adoption of AI is expected to grow, further embedding technology into the core operations of foodservice redistribution.

Growing Emphasis on Sustainability and Waste Reduction

Sustainability has become a central concern in foodservice redistribution, with efforts focused on minimizing environmental impact and reducing waste. Key trends include:

-

Eco-Friendly Packaging: Distributors are increasingly adopting compostable, biodegradable, and recyclable packaging materials to reduce plastic pollution and promote environmental sustainability. This shift addresses consumer demand for environmentally responsible practices and aligns with global sustainability goals.

-

Food Waste Mitigation: Implementing strategies to reduce food waste is a priority. Techniques such as canning, preserving, pickling, and fermenting foods extend shelf life and minimize waste. Additionally, utilizing food protection and preservation ingredients enhances food safety and reduces spoilage.

-

Regulatory Initiatives: Governments are introducing regulations to compel companies to reduce food waste. For example, the European Union has mandated a 10% reduction in food waste from manufacturing and processing, and a 30% per capita reduction in retail, restaurants, food services, and households by 2030.

Evolving Consumer Demands and Their Influence on Redistribution Strategies

Consumer preferences are shifting towards transparency, health, and convenience, influencing redistribution strategies:

-

Transparency and Authenticity: There is a growing expectation for transparency in the supply chain, with consumers demanding information about the origin and handling of their food. Redistribution strategies are adapting by incorporating traceability systems to provide this information.

-

Health and Wellness Focus: Consumers are increasingly seeking healthier food options, prompting redistributors to include a wider range of health-focused products. This trend necessitates adjustments in sourcing and distribution to meet the demand for nutritious offerings.

-

Convenience and Speed: The demand for quick and convenient food options is influencing redistribution strategies to prioritize efficiency in delivery and availability, ensuring that products reach consumers promptly and in optimal condition.

Conclusion

Foodservice redistribution stands as a cornerstone of the modern food supply chain, bridging the gap between manufacturers and foodservice operators with efficiency and reliability. By understanding the redistribution model, recognizing the roles of various stakeholders, and implementing best practices, the industry can navigate its inherent challenges effectively. As technological advancements and sustainability initiatives continue to evolve, embracing these changes will be crucial for all parties involved. Ultimately, a well-orchestrated redistribution system not only streamlines operations but also ensures that consumers receive quality food products promptly, reinforcing the vitality of the foodservice industry.