Distributor vs Manufacturer: What's the Difference?

The relationship between manufacturers and distributors is a key part of the supply chain, influencing how products reach end users. This dynamic is not just about transactions but also about coordination and strategic alignment.

Understanding this relationship is essential for businesses in any industry that rely on manufacturers and distributors to operate. So let’s understand how a mafucturer and distributor’s role differ in the supply chain and how their relationship affects your business.

Table of Contents:

- What is a Manufacturer?

- What is a Distributor?

- Key Differences Between a Manufacturer and a Distributor

- The Challenges of the Manufacturer-Distributor Relationship

- The Importance of Rebates in the Manufacturer-Distributor Relationship

- Overcoming Challenges in the Manufacturer-Distributor Relationship

- Why Manufacturers Need Distributors (and Vice Versa)

- The Role of Technology in Modern Manufacturer-Distributor Relationships

Jump to a section that interests you, or keep reading.

What is a Manufacturer?

A manufacturer is an entity that takes raw materials and transforms them into finished goods. They are the backbone of production within the supply chain, providing the products that distributors, retailers, and ultimately, end consumers rely on. Manufacturers are responsible for designing, developing, and producing products in bulk, which are then distributed through various channels. Without manufacturers, there would be no products to sell, making them a pivotal component of the entire supply chain ecosystem.

Manufacturers operate by converting raw materials, such as metals, plastics, textiles, and chemicals, into finished products through various processes like assembly, molding, machining, or chemical processing. These processes are carried out in factories or plants equipped with specialized machinery, skilled workers, and supply chains of their own to source the raw materials needed for production. The goal is to produce a high-quality, reliable product at scale, ready for distribution by wholesalers, distributors, or sometimes even directly to customers, depending on the business model.

There are different types of manufacturers, ranging from small-scale operations to large global enterprises. Small-scale manufacturers typically focus on niche products or custom-built items. Their operations are often characterized by limited production runs and a focus on craftsmanship, quality, and specialization. In contrast, large-scale manufacturers produce products in mass quantities and often operate multiple factories worldwide. They may focus on consumer goods, electronics, or heavy industries, among other sectors, where cost-efficiency, speed, and uniformity are paramount. These larger manufacturers often face the challenge of balancing high-volume production with maintaining quality standards.

What is a Distributor?

A distributor is an intermediary entity in the supply chain that plays a crucial role in bridging the gap between manufacturers and end-users, including retailers and consumers. Distributors purchase products in bulk from manufacturers and break them down into smaller quantities for resale. They act as a critical link that enables manufacturers to reach wider markets without having to manage complex logistics or retail relationships directly. Distributors ensure that products are available in the right quantities, at the right time, and in the right places, helping manufacturers expand their reach beyond their own production capabilities.

Distributors serve as the vital connection point in the supply chain, managing the flow of goods between the manufacturer and the retailer or end user. They handle the bulk buying from manufacturers, which would be difficult or inefficient for many retailers or individual customers to procure directly. Instead, they store, manage, and distribute these products to wholesalers, retailers, or even directly to consumers in some cases. Distributors significantly simplify the relationship between manufacturers and the end market by managing the complexities of supply, storage, and delivery.

One of the key services provided by distributors is warehousing. Distributors maintain large storage facilities to store the products they purchase from manufacturers. This warehousing capability allows them to manage inventory, hold products until demand arises, and supply goods in a timely manner to customers. Efficient warehousing operations are essential for meeting the fluctuating demands of the market and ensuring that stock levels remain optimal.

In addition to warehousing, distributors often offer marketing and sales support for the products they handle. This can include promoting products, generating leads, and ensuring product visibility in the market. Distributors are typically well-versed in regional or sector-specific markets, which allows them to tailor marketing efforts and sales tactics accordingly. They also provide logistics services, ensuring that products are transported from the manufacturer to the retailer or end-user efficiently, whether it involves arranging shipping, managing customs, or coordinating local delivery.

Exclusive relationships are common between distributors and manufacturers. These exclusive agreements often occur on a regional or sector-specific basis, meaning a distributor may have the sole rights to sell a manufacturer’s products within a specific geographic area or industry segment. Such agreements allow manufacturers to streamline their distribution process and ensure that their products are handled by knowledgeable and trusted partners. Exclusive relationships also create loyalty between both parties, as distributors often commit to purchasing significant quantities of products and promoting them actively in exchange for the exclusive rights to distribute them.

Key Differences Between a Manufacturer and a Distributor

The relationship between a manufacturer and a distributor is vital to the success of the supply chain. However, their core responsibilities and expertise differ significantly, allowing each to play a unique role in the flow of goods from production to consumption.

Manufacturing vs Distribution: Core Responsibilities

The primary responsibility of a manufacturer is to produce goods by transforming raw materials into finished products. They are focused on the design, development, and actual creation of products. Manufacturers control the entire production process, ensuring that products meet quality standards and are ready for distribution. They typically deal with large-scale operations involving extensive production lines and capacity.

On the other hand, distributors are responsible for getting those products into the hands of retailers or end-users. They purchase products from manufacturers, store them in warehouses, and then break them down into smaller quantities for resale. Distributors act as intermediaries that manage the logistical side of getting products from manufacturers to the market. They handle product availability, inventory management, and the smooth flow of goods from the point of creation to the point of sale.

Expertise: Manufacturers in Product Design and Production; Distributors in Customer and Market Expertise

Manufacturers are experts in product creation. Their focus is on innovation, ensuring that products are designed and developed to meet market demands. Manufacturers need to stay ahead of production trends, manage raw materials, and maintain efficient production processes. Their expertise lies in developing the product, managing its quality, and scaling production.

In contrast, distributors are experts in the market and customer needs. They understand regional demands, customer preferences, and how to manage the sales process. Distributors work to ensure that products are marketed effectively and made available in the appropriate retail environments or for direct sales to consumers. Their expertise is in managing relationships with customers, retailers, and sometimes even end-users, ensuring the right products reach the right audience.

Scale of Operation: Bulk Production vs Smaller Order Fulfillment

Manufacturers typically engage in bulk production. Their operations are designed to handle large quantities of products, optimizing the production process to reduce costs and increase output. They focus on mass-producing products to ensure economies of scale, which makes them more efficient and cost-effective in creating large batches of goods.

Distributors, however, handle smaller order fulfillment. They purchase large quantities from manufacturers but sell smaller amounts to retailers or other businesses. Their role is to manage the distribution of products in more manageable lots, ensuring that demand is met with appropriate inventory levels. Distributors may need to adapt to varying demand levels and adjust their stock accordingly, requiring greater flexibility than manufacturers.

Distribution Channels and Markets Served

Manufacturers generally focus on production facilities and may have limited or no direct involvement in selling products to end customers. Instead, they work through distributors to reach the market. Manufacturers often focus on wider geographic or global markets and work with distributors to penetrate specific regional or sector-based markets.

Distributors, in contrast, specialize in market reach and customer relationships. They know the local market dynamics, which allows them to target specific customer segments. Distributors may serve a specific region, retail chain, or even focus on a niche market. They are deeply embedded in their distribution channels, ensuring that products are available at the right locations and times, often providing market-specific insights and feedback to manufacturers.

Pricing: How Manufacturers and Distributors Handle Pricing and Margins

Pricing plays a key role in differentiating manufacturers from distributors. Manufacturers set the base price for their products, considering the cost of production, raw materials, labor, and operational costs. Their pricing strategy typically revolves around bulk sales and establishing price points that allow them to profit while selling large quantities to distributors.

On the other hand, distributors often work with manufacturers' pricing but adjust the final selling price to account for their logistics, warehousing, and value-added services such as marketing and customer support. Distributors may have more flexibility in negotiating prices with retailers or end customers, offering discounts or rebates to increase sales volume. This ability to set the final price allows distributors to control their margins based on market conditions, customer demand, and the competitive landscape.

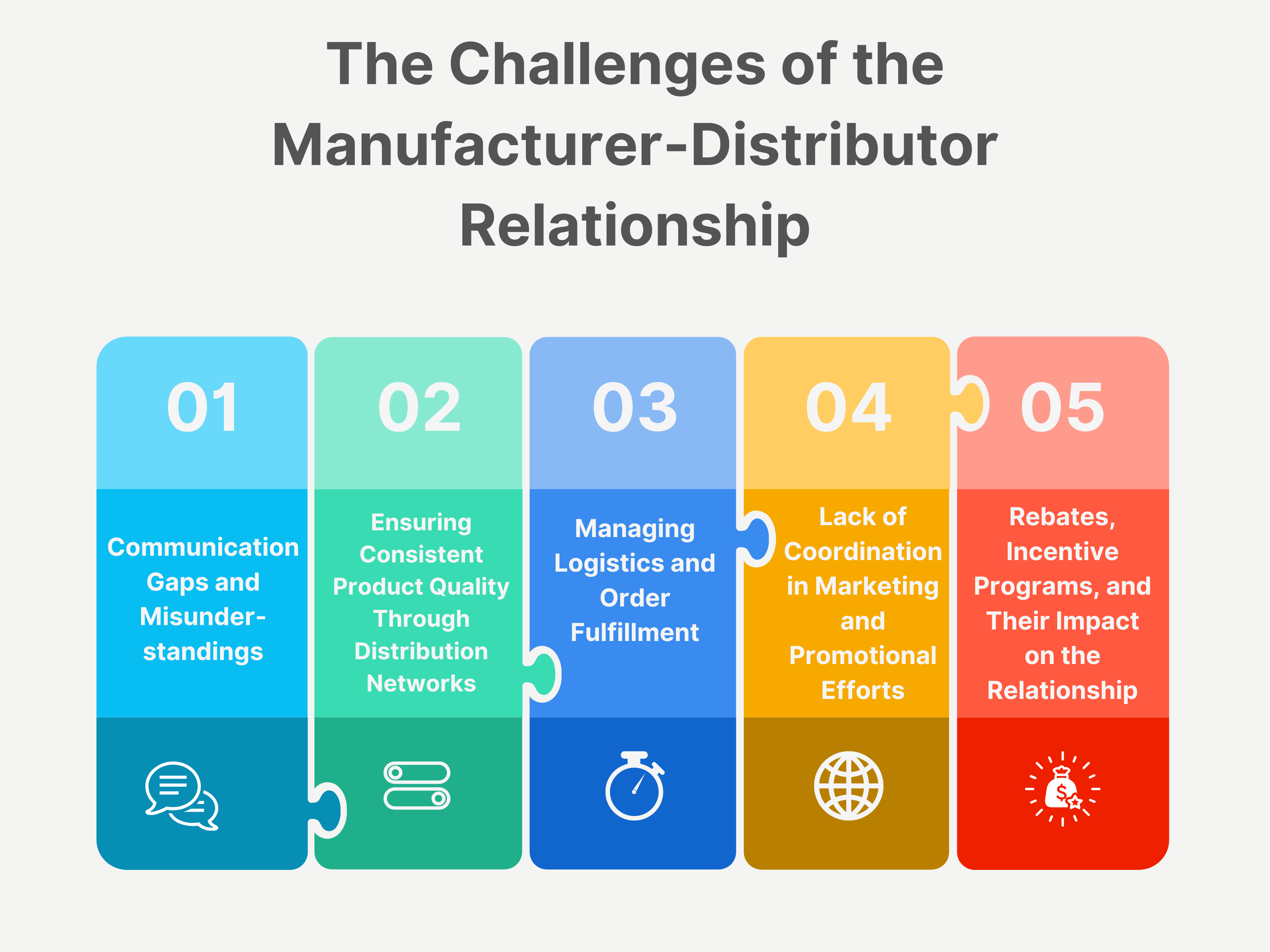

The Challenges of the Manufacturer-Distributor Relationship

The relationship between manufacturers and distributors is fundamental to the supply chain, but it’s not without its challenges. These challenges stem from various aspects of the business, including communication, product quality, logistics, marketing, and incentive programs. Understanding these issues is crucial for fostering a productive and successful partnership.

Communication Gaps and Misunderstandings

A significant challenge in the manufacturer-distributor relationship is the lack of effective communication. Manufacturers and distributors often operate in different environments with distinct goals and priorities. Manufacturers may not fully understand the day-to-day challenges distributors face in the market, such as customer preferences and regional demands. Conversely, distributors may struggle to keep up with production schedules, new product developments, and changes in pricing or delivery terms that manufacturers may not clearly communicate.

This communication breakdown can lead to misunderstandings that impact the flow of goods, disrupt schedules, and cause delays or dissatisfaction on both ends. Without clear, consistent communication, critical details regarding orders, inventory levels, or product specifications can be overlooked, ultimately affecting the efficiency of the entire supply chain.

Ensuring Consistent Product Quality Through Distribution Networks

Maintaining consistent product quality across a vast distribution network is another challenge. Manufacturers focus on creating high-quality products, but once those products leave the factory, it becomes the distributor’s responsibility to handle and deliver them. Variability in product handling, storage, and transportation can impact quality. Distributors may not always have the same quality control measures in place, leading to potential discrepancies in product presentation or condition at the point of sale. This inconsistency can undermine the manufacturer’s brand reputation, as consumers expect the same level of quality regardless of where or how the product is purchased.

Distributors must align their practices with the manufacturer's quality standards to ensure the products meet the expectations of both the market and the manufacturer.

Managing Logistics and Order Fulfillment

Another critical area of challenge is logistics and order fulfillment. Manufacturers typically deal with large-scale production and bulk shipments, while distributors must break down these large quantities into smaller, more manageable orders for retailers or end-users. This creates logistical complexities, particularly when managing inventory, shipping times, and regional demand. A delay or mismanagement at any point in the logistics chain can lead to stockouts, overstock situations, or extended delivery times, all of which disrupt the smooth flow of products to the market.

Moreover, distributors must constantly balance the volume of products with the demand from their customers. A mismatch between supply and demand can lead to inefficiencies or missed sales opportunities, which ultimately affects the manufacturer’s bottom line.

Lack of Coordination in Marketing and Promotional Efforts

Coordinating marketing and promotional efforts is essential for boosting sales, but many manufacturers and distributors struggle with this task. Manufacturers may create marketing materials and promotional campaigns aimed at promoting their products, but without aligning these efforts with the distributors' marketing strategies, these campaigns may not be as effective.

Distributors, who have firsthand knowledge of local markets, may need different kinds of promotional support to appeal to their specific customer base. If manufacturers and distributors fail to align on promotional activities, it can result in a disconnect where marketing initiatives are not tailored to the unique needs of the target audience. This lack of coordination can lead to wasted resources, missed opportunities for cross-promotions, and lower sales than expected.

Rebates, Incentive Programs, and Their Impact on the Relationship

Rebates and incentive programs are commonly used by manufacturers to encourage distributors to sell more products or meet specific sales targets. While these programs can foster stronger relationships by rewarding distributors for their efforts, they can also create tension if not managed properly.

Manufacturers may offer customer rebates to incentivize distributors to stock and sell more of their products. However, if rebate agreements are not clearly communicated or are difficult to manage, distributors can become frustrated. Manual processes, such as tracking rebates through spreadsheets or email communications, often lead to mistakes, delays in payment, and misaligned expectations. In some cases, rebates may not be paid out on time or in full, which undermines trust and loyalty.

Additionally, conflicting incentive structures can lead to issues. Distributors may feel they are not adequately supported by the manufacturer in their promotional or sales efforts, particularly if they are required to make large investments in marketing or stock without clear compensation. Similarly, manufacturers may feel that distributors are not fulfilling their side of the bargain in terms of achieving sales targets or adhering to marketing guidelines.

Effective management of these programs is essential for maintaining a healthy working relationship between manufacturers and distributors. The use of automated rebate management systems can reduce misunderstandings, streamline the process, and ensure both parties are aligned in their goals.

The Importance of Rebates in the Manufacturer-Distributor Relationship

Rebates play a pivotal role in shaping the dynamics between manufacturers and distributors, serving as an effective tool for boosting loyalty, increasing sales, and driving collaboration. For both parties, the strategic use of rebates is essential to foster stronger partnerships, align objectives, and ensure that each side is motivated to meet agreed-upon goals.

The Role of Rebates in Fostering Loyalty and Increasing Sales

Rebates are not just about financial incentives; they serve as a mechanism for building trust and loyalty between manufacturers and distributors. Manufacturers often face competitive markets where multiple companies produce similar products. By offering rebates, manufacturers encourage distributors to prioritize their products, strengthening the distributor’s commitment to their brand. This loyalty is critical as it ensures that distributors continue to stock and promote the manufacturer’s products over competitors’ offerings.

From the distributor’s perspective, rebates incentivize greater sales and stock turnover. Distributors are often working on tight margins, and rebates offer a financial reward for meeting sales targets or committing to larger orders. This, in turn, increases the distributor’s profitability and motivates them to push the manufacturer’s products more actively within their customer networks, thus resulting in higher sales volumes. As a result, rebates create a mutually beneficial cycle where both the manufacturer and the distributor can see tangible growth.

Manufacturer and Distributor Perspectives on Rebate Agreements

Rebate agreements can differ depending on the manufacturer and distributor’s objectives. Manufacturers typically view rebates as a way to secure market share and ensure that their products are prominently featured in the distributor's offerings. A well-structured rebate agreement provides manufacturers with an opportunity to control pricing at the distributor level while encouraging higher sales, better brand presence, and increased market penetration. Manufacturers also use these agreements to foster long-term relationships with distributors, positioning their products as the preferred choice in the market.

On the other hand, distributors generally approach rebate agreements from the perspective of cost management and profitability. For distributors, these rebates reduce the cost of goods sold, which directly impacts their profit margins. The ability to secure higher rebates based on volume or performance-based criteria means distributors have an incentive to sell more and keep their inventory levels stocked. Distributors also rely on clear and transparent rebate terms to avoid discrepancies in payment and ensure that their financial forecasts remain accurate.

While both parties have different goals, a well-structured rebate agreement ensures that manufacturers and distributors can work towards a shared objective: increasing sales and market presence while maintaining a profitable and sustainable business relationship.

How Rebates Can Align Goals and Improve Collaboration

Rebates align the goals of manufacturers and distributors by creating a shared incentive structure. Through mutual agreements, both sides are working toward the same outcome: increased sales and a stronger market position. Manufacturers are incentivized to create attractive rebate offers to encourage distributors to move larger volumes of product. Distributors, on the other hand, are motivated to meet sales targets or focus on specific product lines to qualify for higher rebate tiers, thus benefiting from increased margins.

Rebates also improve collaboration by fostering open communication between manufacturers and distributors. The process of negotiating rebate terms requires discussions about sales strategies, market conditions, and product performance, which allows both parties to understand each other’s needs more clearly. This transparency strengthens the overall partnership, builds trust, and helps avoid misunderstandings or disputes over sales targets or rebate payouts.

Moreover, well-managed rebate programs help manufacturers keep distributors engaged with the brand. By offering targeted incentives, such as rebates tied to specific sales goals or product categories, manufacturers can direct distributor efforts toward strategic objectives, like pushing a new product line or expanding into a new region. This alignment enhances the collaborative efforts between both sides and ensures that both the manufacturer and distributor are actively working together to meet shared objectives.

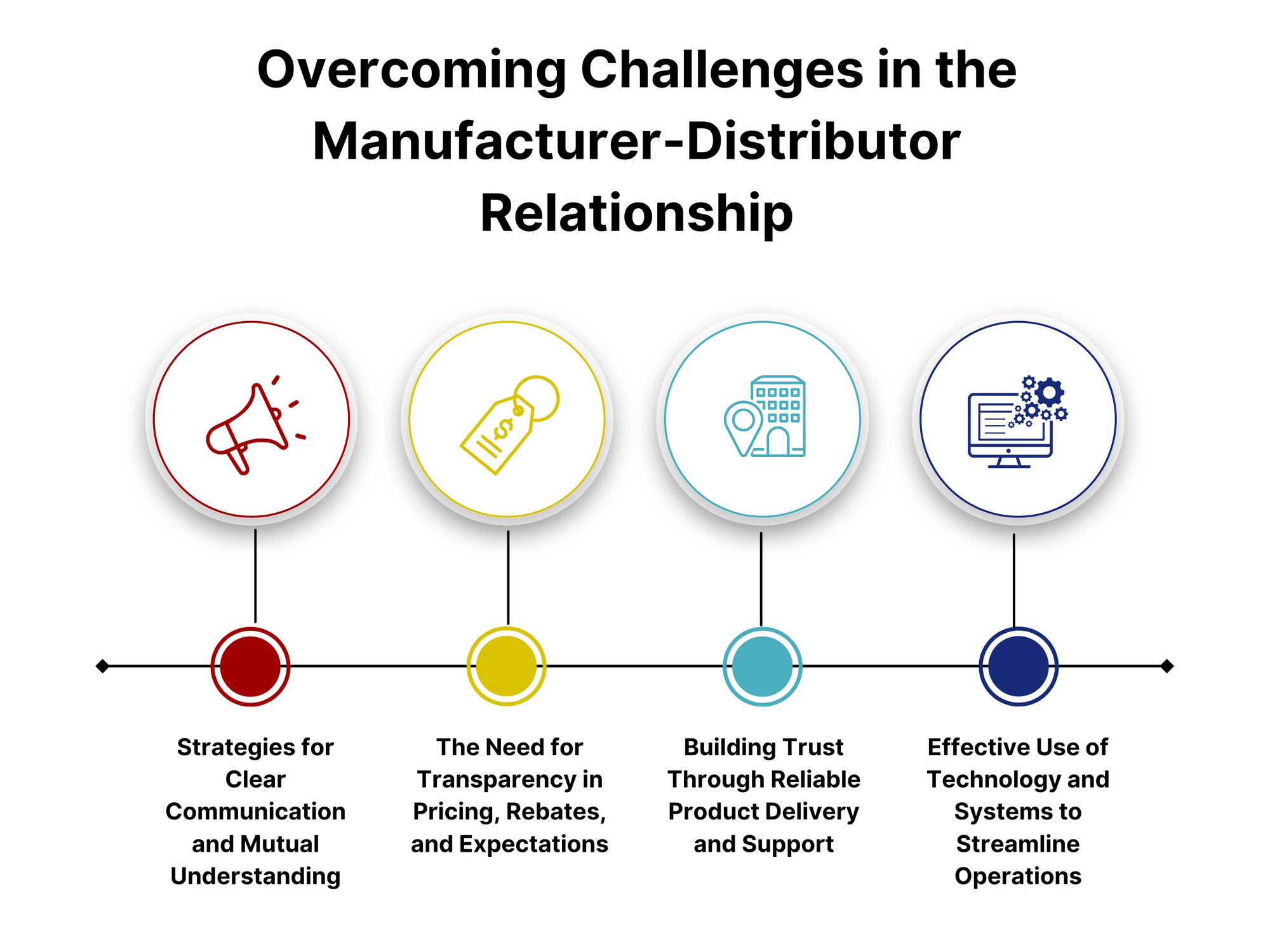

Overcoming Challenges in the Manufacturer-Distributor Relationship

The manufacturer-distributor relationship is critical for success in many industries, but it is also fraught with challenges. Effective collaboration requires addressing communication gaps, ensuring consistent product quality, managing logistics, aligning marketing efforts, and implementing well-structured rebate programs. By adopting specific strategies and leveraging modern tools, manufacturers and distributors can overcome these challenges and establish strong, sustainable partnerships.

Strategies for Clear Communication and Mutual Understanding

One of the biggest obstacles in the manufacturer-distributor relationship is a lack of clear communication. Misunderstandings can arise when manufacturers and distributors are not aligned on goals, expectations, or terms of agreements. To overcome this, both parties must prioritize transparent communication at all stages. This includes regular check-ins, clear documentation of agreements, and openness about challenges faced on either side. Manufacturers should provide comprehensive product training and clear promotional materials, while distributors need to communicate market feedback and customer preferences.

Establishing clear channels for communication, such as dedicated account managers or regular review meetings, helps prevent misinterpretations and ensures both parties are aware of each other’s needs. Regular updates on product availability, changes in market conditions, and shifts in demand can keep both manufacturers and distributors on the same page, leading to more effective decision-making.

The Need for Transparency in Pricing, Rebates, and Expectations

Transparency is key to overcoming many challenges in the relationship. For both manufacturers and distributors, clear, upfront pricing and rebate structures are crucial for avoiding confusion and ensuring mutual satisfaction. Manufacturers should offer transparent pricing models, while distributors should fully understand the terms of rebate agreements, including thresholds, incentives, and eligibility criteria. Any ambiguity in these areas can lead to distrust or disputes over payments, potentially damaging the relationship.

Clear expectations on both sides help in avoiding misunderstandings. Manufacturers need to communicate production timelines, product availability, and pricing adjustments in advance, while distributors should provide insights into customer demands, sales trends, and possible regional variations in product needs. When both parties are on the same page regarding expectations, it fosters a sense of fairness and shared objectives, which helps mitigate potential issues and aligns both sides toward common goals.

Building Trust Through Reliable Product Delivery and Support

Trust is the foundation of any successful partnership, and reliable product delivery plays a crucial role in building and maintaining that trust. Manufacturers must ensure they can meet the agreed-upon timelines for product availability and delivery to distributors. Any delay in product shipments can lead to stockouts, frustrated customers, and, ultimately, lost sales. On the other hand, distributors must maintain consistent communication with manufacturers regarding stock levels and demand forecasts to ensure a smooth flow of products.

To foster trust, manufacturers should also offer strong post-sales support. This includes ensuring that distributors have access to product information, troubleshooting support, and any necessary warranties or returns processes. When both parties consistently meet their obligations—manufacturers delivering products on time and distributors fulfilling customer orders—trust strengthens, making collaboration more effective and long-term.

Effective Use of Technology and Systems to Streamline Operations

In today’s fast-paced business environment, leveraging technology can significantly improve efficiency in the manufacturer-distributor relationship. Inventory management software, for example, helps both manufacturers and distributors track stock levels, product movements, and forecast demand with greater accuracy. When both parties use integrated systems that share real-time data, they can reduce stockouts, prevent overstocking, and optimize order fulfillment. These systems can also help in tracking rebate payments, ensuring that distributors receive their incentives on time and according to the agreed terms.

Additionally, customer relationship management (CRM) software can improve communication between manufacturers and distributors by offering tools to track interactions, manage sales leads, and streamline customer service. With these tools in place, both parties can reduce errors, improve response times, and maintain smoother operations.

Why Manufacturers Need Distributors (and Vice Versa)

The relationship between manufacturers and distributors is symbiotic, with both parties relying on each other to ensure a seamless supply chain and efficient market presence. Each side plays a pivotal role in bringing products from the production line to end customers, creating a mutual dependency that drives business growth and market reach.

The Mutual Dependency Between Manufacturers and Distributors

Manufacturers and distributors are inextricably linked in the supply chain, with each playing an essential role that the other cannot easily replicate. Manufacturers are experts in product development and production, but they do not have the infrastructure or customer-facing experience to effectively manage the distribution of their goods. On the other hand, distributors have the logistical networks, market insights, and customer relationships that manufacturers often lack.

This mutual dependency ensures that manufacturers can focus on scaling production and developing innovative products while distributors can handle the complexities of distribution, sales, and customer service. Without distributors, manufacturers would face significant challenges in reaching a broad customer base, particularly when dealing with the logistical and marketing complexities associated with selling to end users across various regions.

Distributors, in turn, benefit from partnering with manufacturers by securing a steady supply of products, which allows them to focus on the sales cycle, market trends, and customer relationships without having to worry about the complexities of product development or production. Without manufacturers, distributors would lack the goods necessary to sell and build their businesses.

How Distributors Handle the Complexities of Customer Relationships, While Manufacturers Focus on Production

Distributors serve as the customer-facing experts, handling all aspects of the sales and customer relationship that manufacturers typically cannot manage. They possess deep knowledge of local markets, regional preferences, and customer demands, allowing them to effectively tailor their sales strategies to specific consumer needs. Distributors manage a vast network of retailers and end users, serving as the crucial link that translates manufacturer products into customer purchases.

The complexity of customer relationships includes addressing product inquiries, managing returns, providing after-sales support, and handling ongoing communication with retail partners. Distributors must have strong market intelligence and communication skills to anticipate customer needs, adjust stock levels accordingly, and ensure satisfaction at every touchpoint. This customer-centric focus allows manufacturers to focus on what they do best—creating and refining their products without the added burden of navigating market dynamics, consumer behavior, or sales channels.

Manufacturers rely on distributors to not only deliver products to market but also to collect valuable customer feedback. This feedback is crucial for manufacturers to make informed decisions on product development, modifications, and future releases. By working closely with distributors, manufacturers ensure that their products are meeting the needs of end users and retailers.

The Logistical Advantages of Partnering with Distributors for Wider Market Reach

One of the primary advantages of partnering with distributors is their ability to expand a manufacturer’s market reach. Distributors are typically well-established in specific geographic regions and have existing relationships with retailers and end customers. This broadens the manufacturer’s distribution network without requiring the manufacturer to directly manage multiple sales channels.

Distributors handle the logistical challenges of managing inventory, shipping, warehousing, and order fulfillment. They invest in the infrastructure necessary to store and deliver products in large quantities, which would be a significant cost for manufacturers if they tried to handle this in-house. By relying on distributors, manufacturers can access these logistics networks and reach markets that might otherwise be difficult or cost-prohibitive to enter.

Moreover, distributors often have the capability to scale quickly in response to market demand, ensuring that products are available to meet consumer needs. Manufacturers benefit from this scalability, as they can produce goods in large batches without worrying about market saturation or underperformance in certain regions. The logistical expertise and reach that distributors provide allow manufacturers to focus on production and product development while expanding their market presence effectively and efficiently.

The Role of Technology in Modern Manufacturer-Distributor Relationships

Technology has revolutionized the way manufacturers and distributors interact, facilitating smoother and more efficient operations across the supply chain. Digital tools, inventory management systems, and data-sharing platforms have become indispensable for improving transparency, efficiency, and collaboration between the two parties. By leveraging these technological advancements, manufacturers and distributors can not only streamline their processes but also build stronger, more strategic partnerships.

How Digital Tools and Inventory Management Systems (e.g., eSwap) Improve Transparency and Efficiency

Digital tools and modern inventory management systems, such as eSwap, play a critical role in improving the efficiency and transparency of the manufacturer-distributor relationship. These systems allow both manufacturers and distributors to gain real-time visibility into inventory levels, stock movement, and order fulfillment. This level of visibility helps eliminate the information silos that often lead to misunderstandings or errors in order processing.

By using integrated systems like eSwap, both parties can manage stock levels, track products in transit, and adjust inventory based on demand. This is particularly beneficial for manufacturers, who can ensure that production aligns with distributor needs without overproducing or facing stockouts. Distributors, in turn, gain insight into the availability of products, which allows them to better plan their marketing and sales efforts. This improved transparency fosters better coordination, reducing the chances of miscommunication, errors in stock replenishment, and delays in order fulfillment.

Benefits of Real-Time Data Sharing and Synchronized Order Fulfillment

One of the key advantages of incorporating technology into the manufacturer-distributor relationship is the ability to share real-time data. Both parties can track the status of orders, product availability, and delivery timelines, which enhances synchronization between them. Real-time data sharing enables timely decision-making, ensuring that manufacturers are aware of sales trends, product demand, and potential stock shortages in the market. This leads to more accurate forecasting and inventory management, minimizing delays in production and fulfillment.

For distributors, having access to this real-time data means they can act quickly to respond to customer demand, ensuring that orders are fulfilled promptly. It also allows them to make adjustments in stock orders based on current trends, ensuring that they don’t over-order products that aren’t in demand. This synchronized order fulfillment between manufacturers and distributors helps maintain a smooth flow of goods through the supply chain, ultimately improving customer satisfaction and driving sales.

Tracking and Reporting for Rebate Management and Performance Reviews

Technology also plays a vital role in managing rebates and conducting performance reviews, key aspects of the manufacturer-distributor relationship. Rebate management systems, for example, allow both manufacturers and distributors to track the status of rebate claims, monitor performance against agreed-upon targets, and ensure that all deals are being executed according to terms. Without these digital systems, rebate calculations and adjustments would be difficult to manage manually, leading to delays, disputes, and lost revenue.

Digital tools provide a centralized platform where rebate agreements can be reviewed, and real-time tracking ensures that both parties stay aligned in their goals. This visibility into rebate performance allows manufacturers to see which distributors are meeting their targets, enabling them to make adjustments to deals or introduce new incentives. On the distributor side, they can track their progress towards earning rebates, motivating them to sell more or focus on specific product lines that would benefit both parties.

Furthermore, performance reporting capabilities offered by these systems allow both manufacturers and distributors to conduct more effective reviews. They can easily analyze sales trends, product movement, and rebate achievements, making it simpler to assess the effectiveness of their partnership and decide on future strategies. This data-driven approach creates a more informed, objective basis for decision-making, making it easier to identify areas for improvement and boost overall performance.

Conclusion

Understanding the dynamic between manufacturers and distributors is critical for businesses across industries. The relationship between these two parties is foundational to the success of the supply chain, as it directly impacts product availability, market reach, and customer satisfaction. A clear understanding of each party’s role, responsibilities, and challenges helps reduce friction and promotes a more efficient and mutually beneficial partnership.

Ultimately, businesses should take the opportunity to reassess their partnerships and refine their strategies. Continuous improvement and adaptation to industry trends, technology, and market demands are essential for sustaining a successful, long-term collaboration. By investing in clear communication, utilizing technology, and aligning on key objectives, manufacturers and distributors can build stronger, more resilient partnerships that drive success for years to come.